Products

인서트 N-IT series

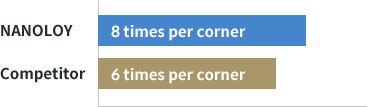

NANOLOY ISO TURNING INSERT

N-IT series

Nano ultrafine powder technology & optimal geometry for aerospace and

automobile parts machining.

→ Longer tool life in heat-resistant alloy, stainless steel machining

Turning insert for ISO S, M material group

- 1. Excellent hardness and wear resistance → ultrafine grade applied

- 2. Designed for ISO S, M materials

(Prevent build up edge and burrs, improve cutting edge wear) - 3. Various geometries → from finishing to roughing machining

PRODUCT FEATURES

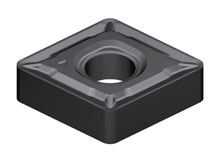

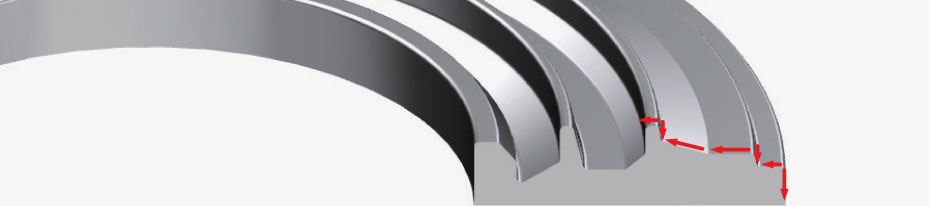

Negative Type

| Chip Breaker | Chip Breaker Design | Features | |

|---|---|---|---|

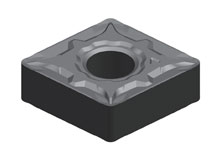

| F11 (Finishing) |

|

|

- Optimized in finishing machining ISO S, M materials - Prevents B.U.E with sharp edge - Enhanced chip evacuation - High rake angle applied in side cutting edge (→ Minimize cutting forces and heat resistance) |

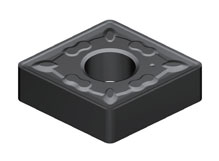

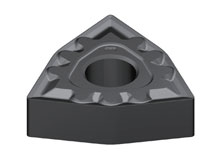

| M11 (Medium) |

|

|

- Optimized in ISO S, M materials - Prevents B.U.E with sharp edge - Strong cutting edge-reduce boundary damage - Wide chip pocket (→ Stable chip evacuation) |

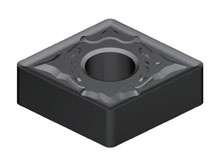

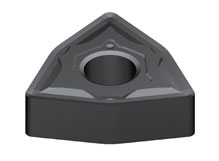

| R11 (Roughing) |

|

|

- Optimized in roughing machining ISO S, M materials - Excellent for cutting edge strength - Designed for deep depth of cut (→ Excellent for deep depth of cut at high feed) |

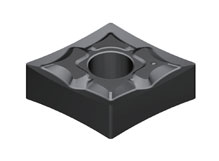

| M22 (Medium) |

|

|

- Optimized in medium machining ISO S, M materials - Prevents B.U.E with sharp edge - Sharp cutting edge & low cutting force - Stable chip pocket (→ Reduce force of chip evacuation ) |

| M51 (Medium / Finishing) |

|

|

- Universal chip breaker - Prevents B.U.E with sharp edge - Sharp cutting edge & low cutting force - Enhanced chip breaker (→ Excellent chip evacuation at Low feed, depth of cut) |

| M21 (Medium) |

|

|

- Optimized in medium machining ISO S, M materials - Prevents B.U.E with sharp edge - Sharp edge & low cutting force - Stable chip pocket (→ Reduce force of chip evacuation) |

| M51 (Medium / Finishing) |

|

|

- Optimized in roughing machining ISO S, M materials - Excellent cutting edge strength - Designed for deep depth of cut (→ Excellent for deep depth of cut at high feed) |

| M51 (Medium / Finishing) |

|

|

- Optimized in medium machining ISO S, M materials - Prevents B.U.E with sharp edge - Sharp edge & low cutting force - Waved cutting edge (→ Reduce cutting force) NANOLOY |

Positive Type

| Chip Breaker | Chip Breaker Design | Features | |

|---|---|---|---|

| F11 (Finishing) |

|

|

- Optimized in finishing machining ISO S, M materials - Prevents B.U.E with sharp edge - Enhanced chip evacuation (→ Stable chip evacuation in Finishing) |

| M11 (Medium) |

|

|

- Optimized in ISO S, M materials - Prevents B.U.E with sharp edge - Strong cutting edge - reduce boundary damage - Wide chip pocket (→ Stable chip evacuation) |

| R11 (Roughing) |

|

|

- Optimized in roughing machining ISO S, M materials - Excellent cutting edge strength - Designed for deep depth of cut (→ Great for deep depth of cut at high feed) |

| M51 (Medium / Finishing) G class |

|

|

- Universal chip Breaker - Prevents B.U.E with sharp edge - Sharp edge & low cutting force - Enhanced chip breaker (→ Excellent chip evacuation at Low feed/depth of cut) |

| 2FM (Medium / Finishing) G / M class |

|

|

- Optimized in ISO S, M materials Finishing and Medium - Prevents sharp edge adhesion - Enhanced chip evacuation - G class machining - G/M class (Selectable) |

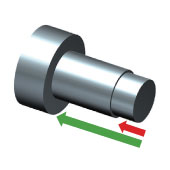

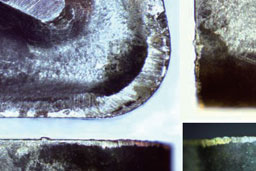

INTERNAL / EXTERNAL TEST (AEROSPACE)

Internal Test

Internal Test (Inconel)

O.D. machining (Inconel)

- Workpiece : Inconel718

- Cutting conditions

vc=60m/min, fn=0.15mm/rev, ap=1.5mm, wet - Item : CNMG120408-F11 NV3025

Internal Test (Stainless steel)

O.D./Facing complex (Stainless steel)

- Workpiece : SUS304

- Cutting conditions

vc=120m/min, fn=0.20mm/rev, ap=2.0mm, wet - Item : CNMG120408-M11 NV3025

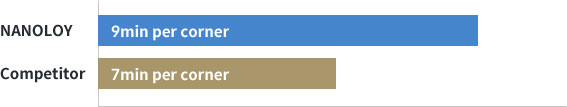

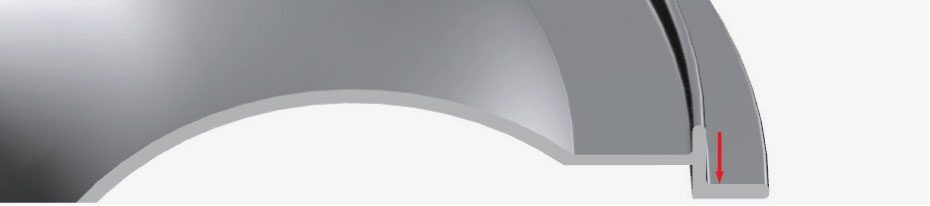

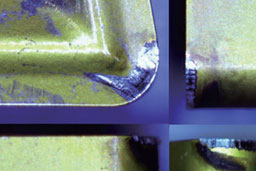

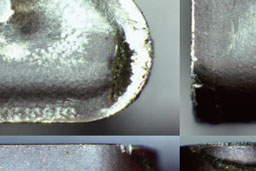

External Test 1. (Aerospace, C263 Nimonic263)

Aerospace Parts_Flange Type Housing

- Workpiece : nimonic263 (forging), max. dia 680mm

- Cutting condition : vc75m/min, fn0.25mm/rev, ap1~2mm

- Machining type : vertical, O.D, facing, wet

- Item : CNMG120412-R11 NV3025

| R11 NV3025 | Competitor "K" | |

|---|---|---|

| Image |  |

|

| Tool life |  |

|

| Results | Increased tool life 150% | |

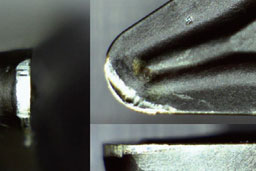

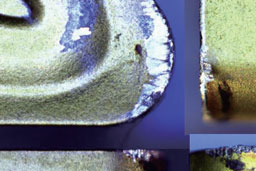

External Test 2. (Aerospace, Mixed_Inconel718+RENE)

Aerospace Parts_Flange Type Housing

- Workpiece : Mixed (inconel718+RENE), max. dia 900mm

- Cutting condition : vc32m/min, fn0.1mm/rev, ap0.45mm

- Machining type : vertical, O.D, facing, wet

- Item : CNMG120408-M11 NV3005

| R11 NV3025 | Competitor "I" | |

|---|---|---|

| Image |  |

|

| Tool life |  |

|

| Result | Increased tool life 120% | |

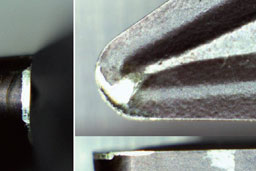

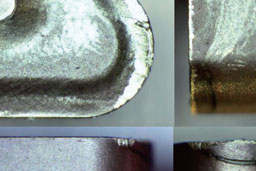

Aerospace Parts_Seal-A/O, Trans External Test 3. (Aerospace, RENE41)

Aerospace Parts_Flange Type Housing

- Workpiece : RENE41, max. dia 880mm

- Cutting condition : vc32m/min, fn0.1mm/rev, ap0.45mm

- Machining type : vertical, O.D, wet

- Item : WNMG080408-M21 NV3005

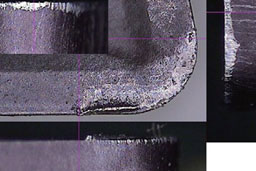

| M21 NV3005 | Competitor "S" | |

|---|---|---|

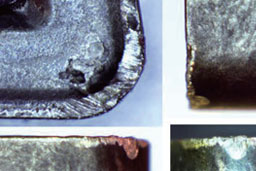

| Image (OP10) |

|

|

| Image (OP10) |

|

|

| Result | Better wear resistance | |

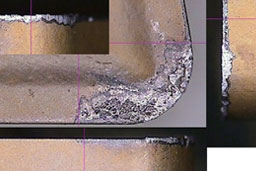

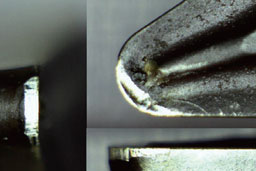

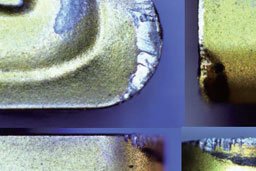

External Test 4. (Aerospace, Mixed_Inconel718+RENE)

Aerospace Parts_Seal-A/O, Trans

- Workpiece : mixed (inconel718+RENE), max. dia 880mm

- Cutting condition : vc33m/min, fn0.1~0.15mm/rev, ap0.5mm

- Machining type : vertical, facing, wet

- Item : VCGT160408-2FM NV3025

| 2FM NV3025 | Competitor "I" | |

|---|---|---|

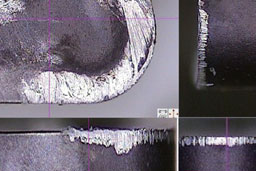

| Image (OP10) |

|

|

| Image (OP10) |

|

|

| Result | Excellent wear resistance in equal machining | |

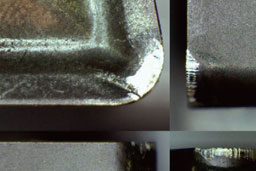

External Test 5. (Aerospace, Inconel718, Heat Treatment)

Aerospace Parts_Stack-Ring

- Workpiece : inconel718, max. dia 495mm

- Cutting condition : vc45m/min, fn0.15mm/rev, ap1.0mm

- Machining type : vertical, O.D, wet

- Item : DNMG150612-M11 NV3005

| M11 NV3005 | Competitor "I" | |

|---|---|---|

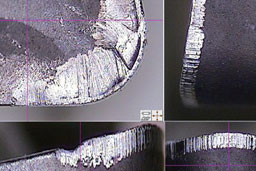

| Image (OP10) 11min |

|

|

| Image (OP10) 15min |

|

|

| Result | Excellent wear resistance and toughness in equal machining | |