Products

인서트 N-MT series

NANOLOY ISO GROOVING INSERT

N-MT series

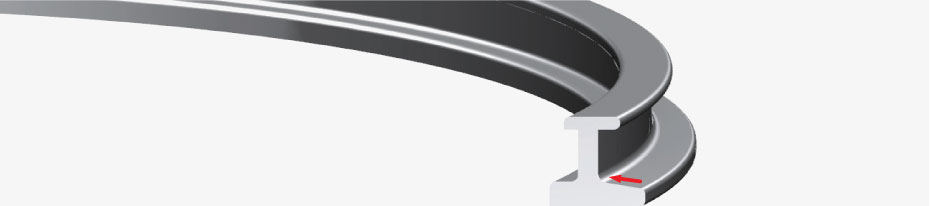

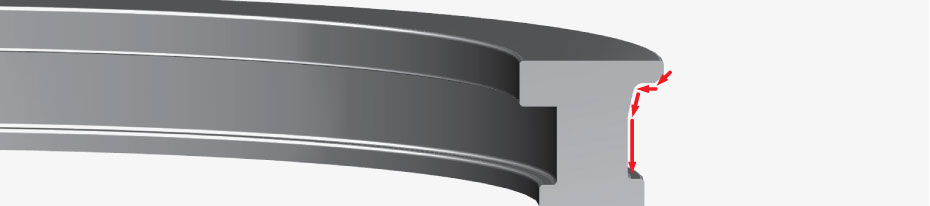

Applying stable clamping system, N-MT series guarantee high quality and high efficiency machining.

Grooving inserts & holders

- 1. Stable clamping system for specially designed grooving machining

- 2. Various machining available (grooving, parting off, turning)

- 3. Guarantees high quality and high efficiency machining in aerospace and automobile industry.

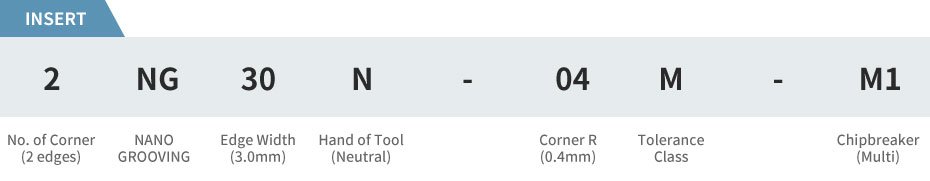

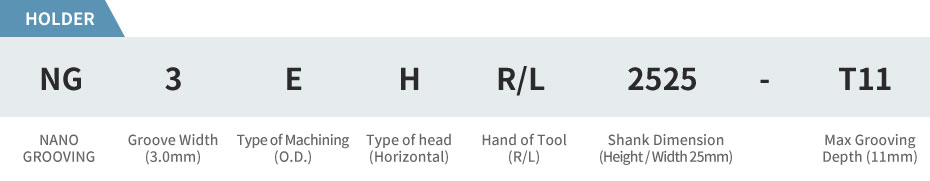

NUMBERING SYSTEM & FEATURES

Numbering System (Insert & Holder)

Geometry (Insert Chip Breaker)

F1 (light cutting) chip breaker

Sharp edge & low cutting force

- Machining type : grooving / parting off

- Features : low cutting force(low-load machining)

- Application : optimized in ISO S, M materials

M or G class

M1 (multi) chip breaker

Various machining type & excellent tool life & chip evacuation

- Machining type : grooving / turning / parting off

- Features : excellent chip evacuation

- Application : optimized in all materials

M class

F1M (light cutting) chip breaker

Sharp cutting edge & Improved chip control

- Machining type : grooving / parting off

- Features : low cutting force(low-load machining)

- Application : optimized in ISO S, M materials

M or G class

M1 (radius type_profile machining) chip breaker

Various machining type & excellent tool life & chip evacuation

- Machining type : grooving / profiling

- Features : excellent chip evacuation

- Application : optimized in all materials

M or G class

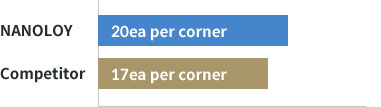

APPLICATION (INTERNAL / EXTERNAL TEST)

Internal Test

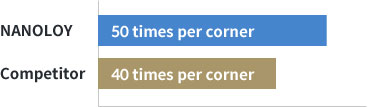

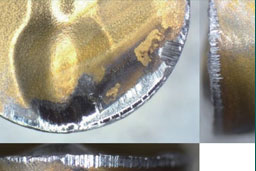

INTERNAL TEST (INCONEL)

Grooving machining (Inconel)

- Workpiece : Inconel718

- Cutting conditions : vc=45m/min, fn=0.1mm/rev, ap=5.0mm wet

- Item : 2NG30M-04R-F1/ AT3065

Grooving machining (Inconel)

- Workpiece : Inconel718

- Cutting conditions : vc=50m/min, fn=0.1mm/rev, ap=6.0mm wet

- Item : 2NG30M-04R-F1/ AT3065

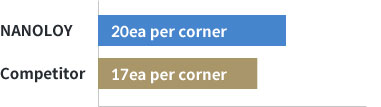

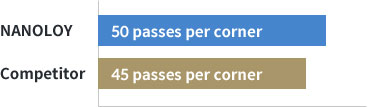

INTERNAL TEST (STAINLESS STEEL)

Cut-off machining (Stainless Steel)

- Workpiece : SUS316

- Cutting conditions : vc=120m/min, fn=0.12mm/rev, ap=4.0mm wet

- Item : 2NG40M-04R-M1/ TS3065

O.D. machining (Stainless Steel)

- Workpiece : SUS316

- Cutting conditions : vc=100m/min, fn=0.15mm/rev, ap=1.0mm wet

- Item : 2NG40M-04R-M1/ TS3065

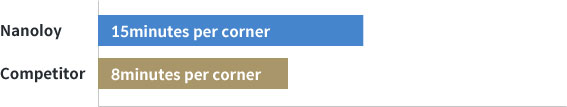

External Test 1. (Aerospace, Inconel718)

Aerospaceparts_Flange Type Housing

- Workpiece : inconel718, max. dIA 570mm

- Cutting condition : vc45m/min, fn0.1mm/rev, ap2.0mm

- Machining type : O.D, facing, profiling, wet

- Item : 2NG50R-25G-M1 NV3025

| M1 NV3025 | Competitor "T" | |

|---|---|---|

| Image 8min |  |

|

| Tool life |  |

|

| Result | Increased tool life 180% | |

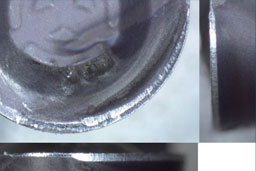

External Test 2. (Aerospace, Inconel718)

Aerospaceparts_Case, HPT STTR

- Workpiece : inconel718, max. dia 680mm

- Cutting condition : vc35m/min, fn0.15mm/rev, ap5~8mm

- Machining type : vertical, O.D, grooving, shouldering, wet

- Item : 2NG80N-08G-F1 NC3005

| F1 NV3005 | Competitor "I" | |

|---|---|---|

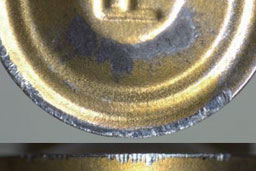

| Image (OP10) 10min |

|

|

| Image (OP10) 10min |

|

|

| Result | Excellent wear resistance and toughness | |

External Test 3. (Aerospace, Inconel718)

Aerospaceparts_Flange Type Housing

- Workpiece : inconel718, max. dia 570mm

- Cutting condition : vc60m/min, fn0.12mm/rev, ap2.0mm

- Machining type : O.D, facing, profiling, wet

- Item : 2NG50R-25G-M1 NV3005

| M1 NV3005 | Competitor "S" | |

|---|---|---|

| Image 8min |  |

|

| Tool life |  |

|

| Result | Excellent wear resistance | |

External Test 4. (Aerospace, Inconel718)

Aerospaceparts_Case, Comp AFT Inner STG

- Workpiece : inconel718, max. dia 542mm

- Cutting condition : vc40m/min, fn0.15mm/rev, ap0.7mm

- Machining type : vertical, O.D, facing, profiling, wet

- Item : 2NG50R-25G-M1 NV3025

| M1 NV3025 | Competitor "T" | |

|---|---|---|

| Image (OP10) 13min |

|

|

| Image (OP10) 7min |

|

|

| Result | Excellent wear resistance and toughness | |